The unique graphic T-shirts we wear are often the most immediate, personal form of communication, and nothing speaks louder than a great Graphic T-shirt. It’s a canvas of cotton, a wearable billboard, a lightning-fast way to project personality, passion, or humour to the world. For many, the T-shirt is merely a finished product purchased from a rack or an online store; the complex journey it takes from a fleeting thought—a mere Design Inspiration—to a tangible, comfortable garment is often overlooked.

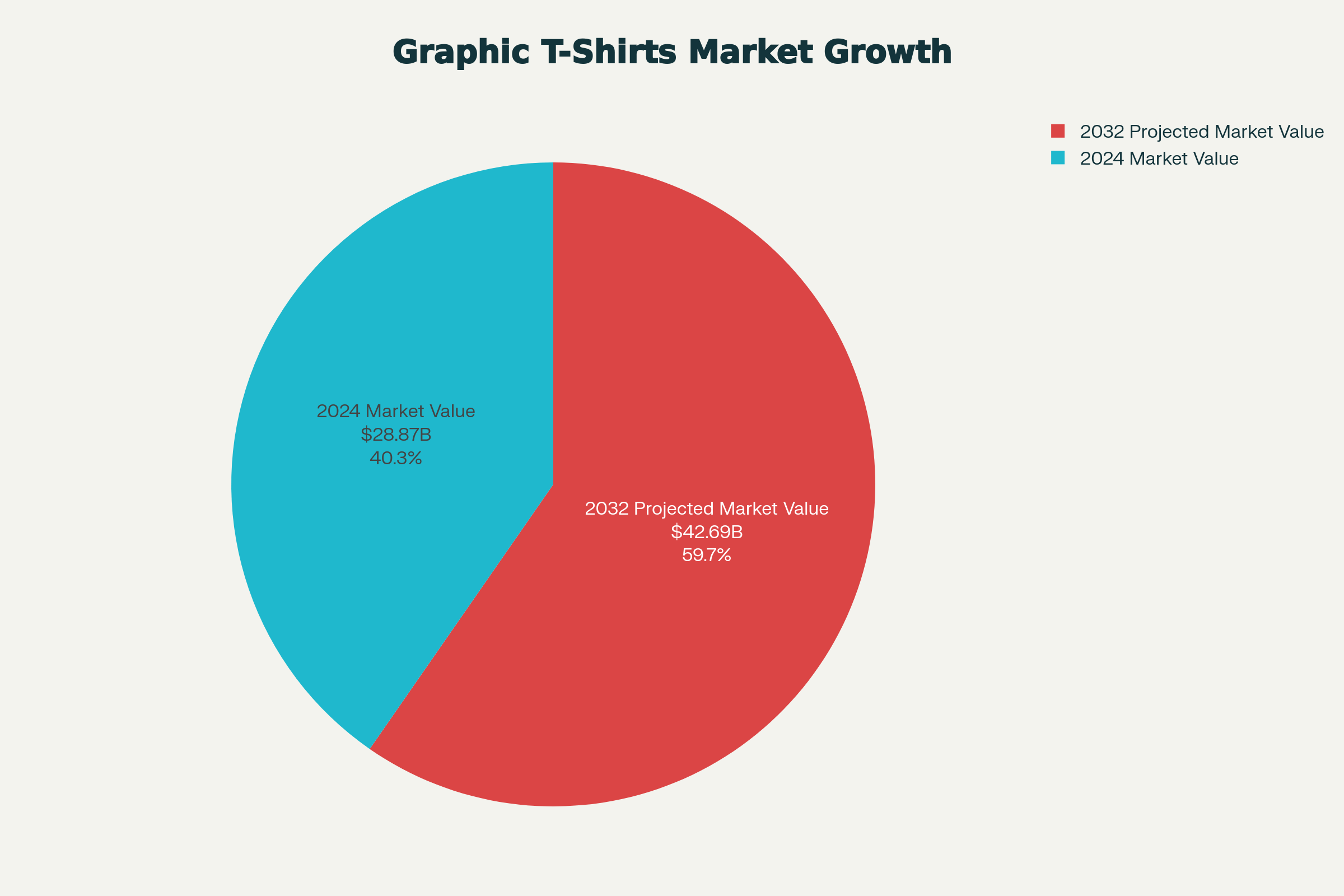

This journey, from the ethereal world of ideas to the tactile reality of the closet, is a fascinating fusion of artistry, technology, and textile science. It is the story of how a bold concept is meticulously nurtured and transformed into a Unique Graphic Tee that not only looks good but feels good and lasts. The scale of this market demonstrates its cultural relevance: the global Graphic T-Shirts Market was valued at a massive USD 28.87 Billion in 2024, with projections showing continued strong growth toward $42.69 Billion by 2032, according to Verified Market Research.

This comprehensive guide sheds light on the entire pipeline. We will dive deep into every phase, starting from the initial mental spark—the moment a message is deemed worthy of permanent ink—through the rigorous steps of textile selection, design digitisation, and complex printing methods, right up until the moment that pristine Graphic T-Shirt is ready for its first wear.

Understanding this process reveals why some T-shirts become beloved, long-lasting staples while others quickly fade into obscurity. It is a testament to the effort involved in creating high-quality, expressive apparel that truly connects with the wearer. The journey of any T-shirt worth its salt is one defined by precision and passion, ensuring that the story on the fabric resonates as much as the comfort of the cotton itself.

I. The Spark: Conceptualise and Ideate

Every exceptional piece of apparel begins as an answer to a question: What story are we telling? In the competitive world of T-shirt design, where brands like Bewakoof and Redwolf constantly fight for attention, genuine originality is paramount. The first stage, to conceptualise a graphic t-shirt, is perhaps the most crucial. It involves market research to identify cultural trends, niche interests, and social commentary that is both relevant and fresh. For a brand focusing on specific communities, like gym enthusiasts or bikers, the concepts must spring directly from the lived experience of that audience. It is about distilling complex feelings or inside jokes into single, powerful visual or textual ideas. This initial phase is not about sketching; it’s about brainstorming, mood boards, and finding a voice.

A key element in the modern statement T-shirt market is the successful development of Witty Slogans. These require a careful balance of brevity, humour, and relatability. A slogan that forces a double-take or a genuine smile is far more likely to be worn repeatedly than a generic phrase. It requires writers and marketers to truly immerse themselves in the zeitgeist, understanding what people are talking about right now, and how that conversation can be encapsulated in an iconic line.

For instance, a statement graphic t-shirt that captures the shared experience of remote work or the absurdity of modern dating achieves viral potential because it creates an instant bond between the wearer and the observer. The power of a successful T-shirt lies in its ability to start a conversation before a single word is spoken. This demands that designers conceptualise with deep empathy for the target consumer.

The process of finding genuine Design Inspiration often involves looking beyond fashion itself. It might be found in vintage poster art, architecture, music history, or even scientific diagrams. A truly great design is cross-pollinated, taking an aesthetic cue from one domain and applying it creatively to another. After the core idea and messaging—the Witty Slogans—are locked in, the idea transitions from a simple written concept to a visual wireframe. Designers begin experimenting with typography, graphic balance, and colour palettes, ensuring the emotional tone of the concept is perfectly matched by the visual execution. This preliminary sketching and mood-setting ensures that the final design is not just a picture on a shirt, but a cohesive piece of wearable art, capable of capturing attention in a crowded online marketplace.

II. Designing and Digitising the Unique Graphic T-Shirt

Once the concept is solid, the technical work of the T-Shirt Design Process begins in earnest. This is where the rough ideas are solidified into high-resolution, print-ready files. Specialised software like Adobe Illustrator and Photoshop are the tools of choice, used to meticulously refine vectors, fonts, and colour separations. Every line must be precise, every colour defined by its specific Pantone code, and every element checked for scalability.

The digital file must be prepared to handle the demands of various printing techniques, which require different types of files—vector art for screen printing, and raster images for photorealistic prints. Achieving this level of technical fidelity is essential, as the tiny flaw in the source file will be magnified on the final garment. It is important to note that the custom printing segment is booming, with the global Custom T-shirt printing market valued at over $5.16 billion in 2024, projected to nearly double by 2030, highlighting the consumer drive toward personalised fashion and graphic T-shirts.

This technical refinement is especially critical when creating a Custom T-shirt. Whether it’s an Oversized T-shirt favoured by streetwear enthusiasts or a standard athletic fit for gym-goers, the design must be mock-up tested on the exact template of the garment. The placement—how high the graphic sits from the neck seam, how far it wraps around the side—is as important as the design itself. A design that looks perfect on a flat screen can look awkwardly placed when draped over a human body, especially in the looser, contemporary Oversized T-shirt style.

Artists must account for the natural curvature and stretching of the fabric, particularly around the chest and shoulder seams. This stage often involves printing test mock-ups on paper, or even making sample transfers onto blank tees, to confirm proportional integrity.

The complexity of the T-Shirt Design Process means that designers must be technical experts as much as they are artists. They must constantly consider the constraints of the chosen fabric and the limitations of the available colour palette. For example, a design intended for a dark fabric must use a specific white underbase layer to ensure colour vibrancy, a step that is factored into the file preparation itself. This technical knowledge ensures that the artistic vision for the Custom T-Shirt is perfectly translated into a manufacturing instruction. This stage acts as a vital quality control gateway, ensuring that the product is viable and ready for the mass-production environment.

III. Choosing the Canvas and Print Techniques

The foundation of any great T-shirt is the fabric itself—the canvas on which the design will live. The decision on choosing the Best Fabric significantly impacts the shirt’s feel, drape, longevity, and even its print quality. While polyester is popular for athletic wear due to its moisture-wicking properties, 100% cotton remains the benchmark for casual statement wear.

Within cotton, there are tiers of quality, from standard carded cotton to high-end Supima or Pima cotton, renowned for its extra-long fibres that create a softer, more durable product. Increasingly, environmentally conscious brands prioritise Organic Cotton, which is grown without toxic pesticides and chemical fertilisers, appealing to a segment of consumers who value sustainability as much as style.

Consumer demand for sustainable options is transforming textile sourcing. The global market for Organic Cotton is projected to reach US$733.3 million by 2030, driven heavily by the apparel segment, which already holds over 60% of the organic cotton market share (DataM Intelligence). This shift underscores the need for brands to focus on choosing the Best Fabric not just for comfort, but for ethical production.

Once the canvas is selected, the manufacturing team determines the appropriate printing technique. The two dominant methods are Screen Printing and Direct-to-Garment Printing (DTG), each suited for different outcomes.

Screen Printing: This classic method involves pushing ink through mesh screens onto the fabric. It is the most cost-effective solution for large-volume orders with designs that use a limited number of colours. The result is a vibrant, highly durable print that sits slightly raised on the fabric. However, it is labour-intensive for complex, multi-colored images, requiring a new screen for every colour in the design. For simple, bold designs, like most single-colour Witty Slogans, Screen Printing is often the superior choice for longevity.

Direct-to-Garment Printing (DTG): This technique works much like an oversized inkjet printer, spraying specialised aqueous inks directly onto the textile. Direct-to-Garment Printing (DTG) is perfect for complex, high-detail, photorealistic designs that involve numerous colours and gradients. The adoption of this digital technology is accelerating, with the DTG printing market projected to grow at a CAGR of 13.5% through 2032, driven by e-commerce and the demand for personalisation (Persistence Market Research).

This makes it ideal for the intricate artwork sometimes needed for a Unique Graphic Tee. Organic Cotton is particularly favoured for DTG, as the natural fibres absorb the water-based inks perfectly, resulting in vibrant, high-quality prints.

IV. Production and the Final Quality Check

With the digitised design prepared and the fabric and printing method finalised, the project moves into the full Apparel Production phase. This involves cutting the fabric, sewing the T-shirts, and then applying the print. For high-volume production, industrial-grade computerised cutting machines ensure thousands of panels are cut precisely to the specified pattern and size, minimising textile waste. The sewing process is automated for basic construction, but still requires skilled technicians for precision areas like necklines and seams.

A massive paradigm shift in the apparel industry is the rise of the Print-on-Demand (POD) model. Instead of producing thousands of speculative inventory pieces, which carries significant financial risk, the Print-on-Demand approach means a T-shirt is only printed after a customer places an order. This zero-inventory model minimises waste, reduces storage costs, and allows brands to rapidly test and iterate on new designs. The POD market itself is demonstrating explosive growth, projected to achieve a Compound Annual Growth Rate (CAGR) of over 20.89% between 2025 and 2033 (IMARC Group).

This growth rate solidifies POD as a transformative model for the entire Apparel Production landscape. This system is invaluable for niche brands, allowing them to release hundreds of unique designs with minimal upfront investment. While POD often uses Direct-to-Garment Printing (DTG) due to its low setup time, it places extreme importance on efficiency and speed in the fulfilment process.

Regardless of the production method—traditional manufacturing or Apparel Production via POD—the final step is quality control. The entire success of the T-shirt brand rests on the Quality and Craftsmanship of the finished product. Checks include: ensuring the print is centred and defect-free; verifying that the stitching is strong and even; measuring the finished garment against the size specification; and testing the wash-fastness of the ink. Only after passing these rigorous inspections is the T-shirt folded, packaged, and labelled, ready to be shipped from the factory to the customer’s door.

V. From Factory to Final Wear

The final leg of the journey is fulfilment and delivery. Packaging must protect the garment while also communicating the brand’s commitment to Quality and Craftsmanship. The choice of materials, whether sustainable paper or recyclable plastics, reinforces the brand’s identity. For the customer, receiving a Custom T-shirt is an experience. It’s the excitement of unboxing and finally holding the physical manifestation of an idea—the culmination of months of work by designers, textile experts, and printers.

This comprehensive journey underscores the value of what you wear. A high-quality graphic T-shirt is not cheap for the brand to produce, but its value lies in its durability, comfortable feel, and, most importantly, its ability to express a distinct point of view. It’s a testament to innovation, turning a simple piece of clothing into a powerful item of self-expression. The next time you slip on a comfortable, expressive Unique Graphic Tee, you’ll know that you’re wearing much more than just cotton—you’re wearing a story, meticulously woven, designed, and printed, all the way From Concept to Closet.

[…] I’ve watched the apparel market—especially the quirky, pop-culture and relevant graphic t-shirt segment—become increasingly crowded. Every day, it seems like another generic brand pops up selling the […]